The device is an automatic capacitor filling device.

Realize automatic vacuum suction of raw materials, automatic stirring, and heating vacuum to remove bubbles (umbrella shaped structure). The stirring tank is composed of a main agent tank and a hardening agent tank. The two raw materials are mixed using static mixing, and after mixing, it is automatically filled with glue under vacuum environment, and the filling method adopts single fixture and multi-point fixed-point filling. This device is a glue line connection device.

It is used for curing in-case capacitors before glue injection of vehicle mounted capacitors. The electric heating tube is the heat source, the blower realizes the internal circulation of the hot air, and realizes automatic feeding and discharging through jigs, cylinders, chains, etc. This equipment is a glue line equipment, and the heating time can also be customized according to customer needs.

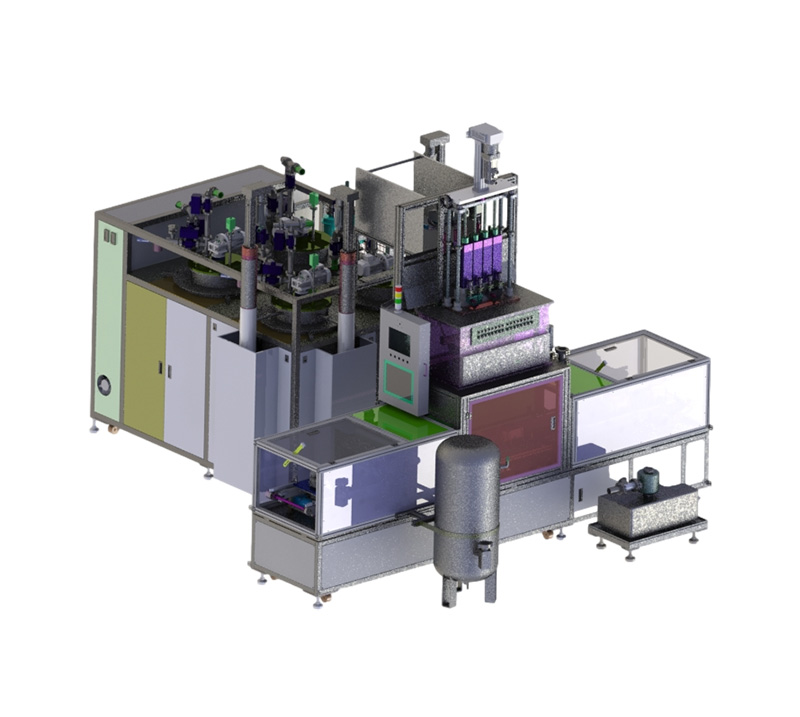

This device is an automatic glue filling device for vehicle mounted capacitors.

Realize automatic vacuum suction of raw materials, automatic stirring, and heating vacuum to remove bubbles (umbrella shaped structure). The stirring tank is composed of a main agent tan and a hardening agent tank. The two raw materials are mixed using static mixing, and after mixing, it is automatically filled with glue in an atmospheric pressure environment. The glue filling method adopts a single jig with a single point of movement. This device is a glue filling line device.

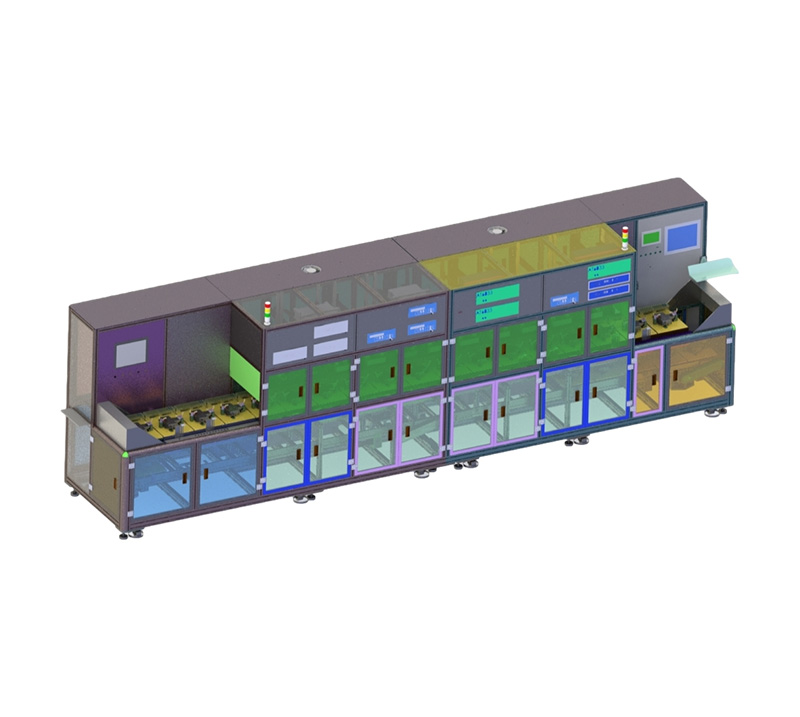

This equipment is suitable for capacitor resin hardening devices. The equipment can be divided into feeding area, material handling area, resin hardening area, resin pre-curing area, resin hardening material loading and cooling area, discharge area. The temperature and cycle time in the oven can be set, and can be used as a universal equipment. This device is a glue line device, and the heating time can also be customized according to customer needs.

This equipment is a capacitor automatic inspection and selection device.

It consists of a structure for handling products to be tested, an inspection mechanism, and a data

processing device. The product is manually mounted on the fixture, moved along with the work

station, passed through the inspection mechanism of each work station, and inspected in sequence.

The product is judged to be good or bad according to the set contents of the inspection. The alarm is

generated when the defective product is moved to the defective product exit station, and after the

defective product is removed manually, the alarm is reset and the inspection continues to run.

Each inspection station can perform manual inspection independently.

The qualified products will be manually discharged at the qualified product discharging station.