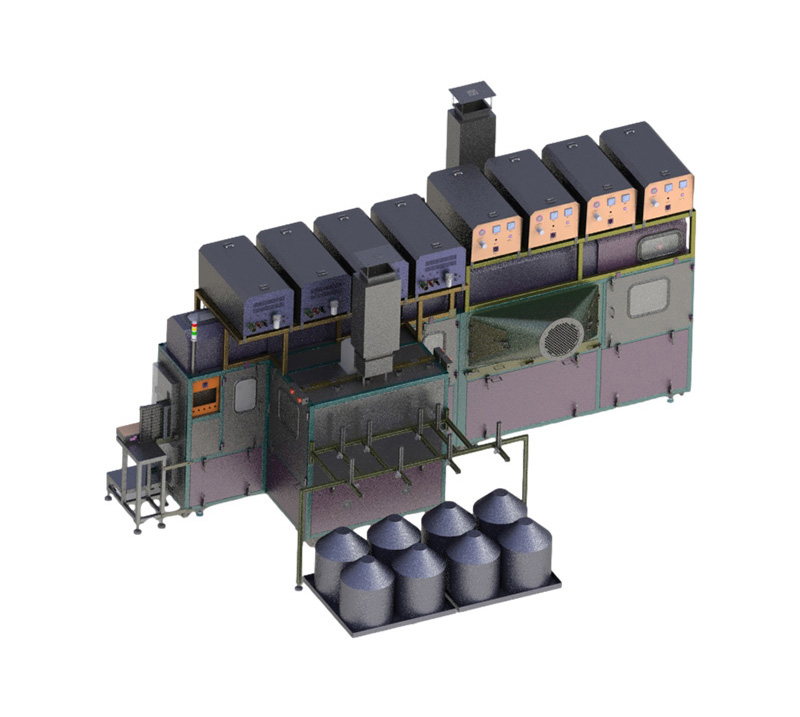

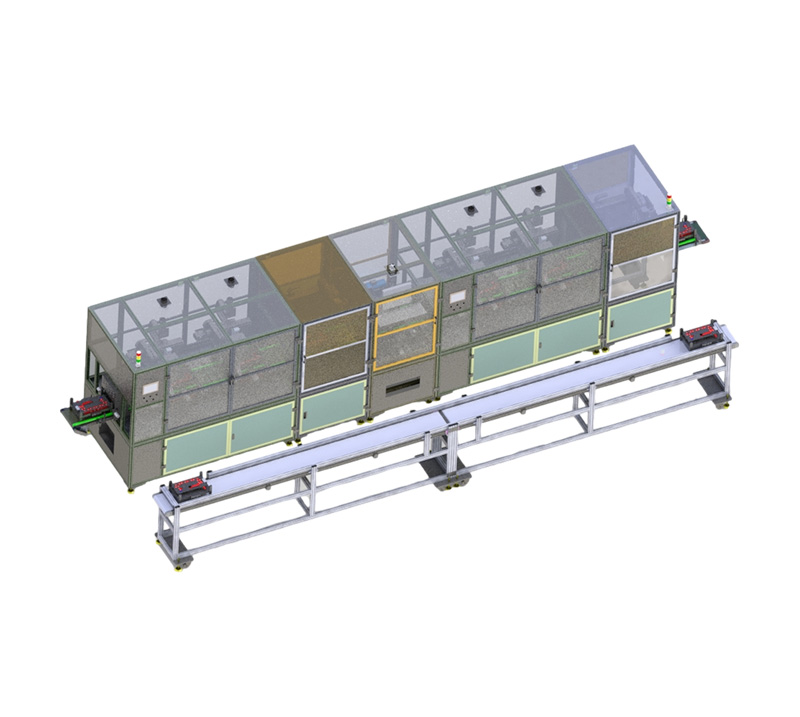

The supplied material of the equipment can be connected to the winding machine or belt supplied material, and the six-axis robot is used to handle the product and 12 stations to be hot pressed at the same time, and each station presses an element separately to flatten and shape the element of the film capacitor, and can achieve traceability of element pressure, temperature and displacement; belt unloading.

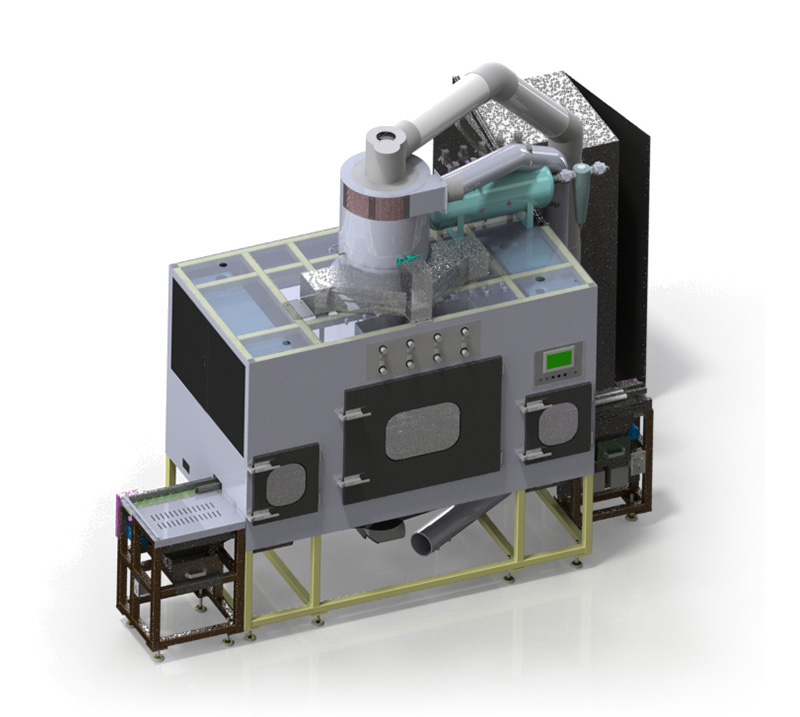

Suitable for metallized film capacitor element spraying, it can be sprayed with zinc, zinc tin alloy, or zinc aluminum alloy. The supplied material is a manually stacked spraying jig, which is manually placed on the loading platform and automatically hooked. The unloading and loading position are in the same place and manually picked up, reducing personnel movement to improve efficiency. The spraying adopts a 4+4 method, and the material utilization rate of the spraying is more than 10% higher than other types of spraying machines.

This equipment is suitable for cleaning the arc surface of metallized film capacitor elements after spraying. The element is cleaned by spraying with glass sand and striking the arc surface of the element.

The discarded spray dust and glass sand that have been shot down are automatically de-dusted, separated, and recleaned through the cyclone separation device and dust removal equipment in the chamber; It is gentler than the traditional roller type and effectively protects the spray layer from impact. The equipment is manually loaded and discharged to a separate receiving tray, or the receiving method can be customized according to customer requirements.

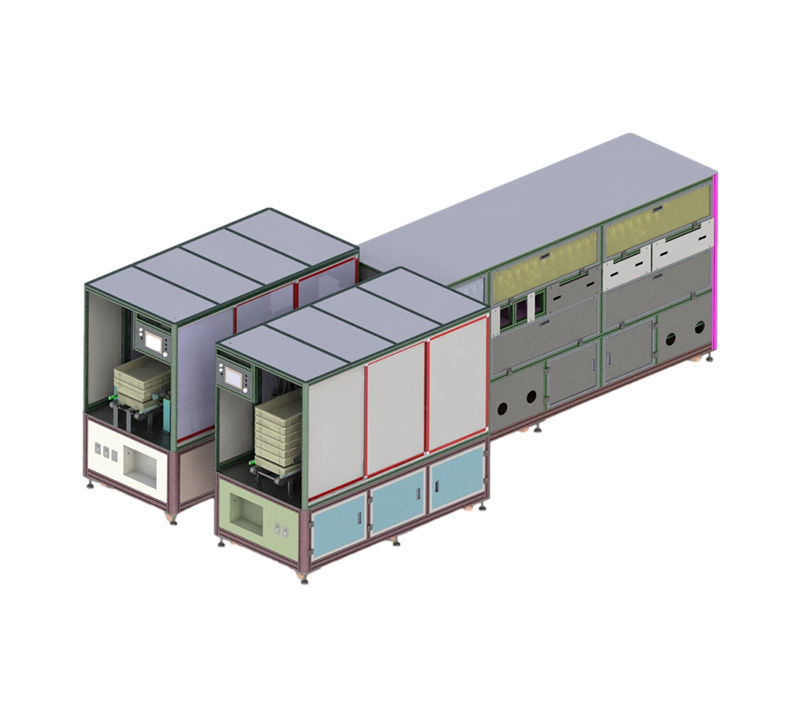

This equipment is used for metallized film capacitor element clearing and sorting, the elements are supplied to the testing fixture of the host machine through the element feeding mechanism, and the elements clamped on the fixture move grid by grid and are electrically connected to the configuration of each test department to complete each inspection item. Through the inspection to determine whether the element is good or not, the defective products are classified and discharged, and the qualified products are sorted out by the transfer mechanism to the element unloading belt. The equipment needs to be manually arranged to the special rubber frame for loading and unloading, and the loading and unloading method can be customized according to the customer's demand.

This equipment is used for metallized film capacitor element clearing and sorting, the elements are supplied to the testing fixture of the host machine through the element feeding mechanism, and the elements clamped on the fixture move grid by grid and are electrically connected to the configuration of each test department to complete each inspection item. Through the inspection to determine whether the element is good or not, the defective products are classified and discharged, and the qualified products are sorted out by the transfer mechanism to the element unloading belt. The loading and unloading methods can be customized according to customer needs.

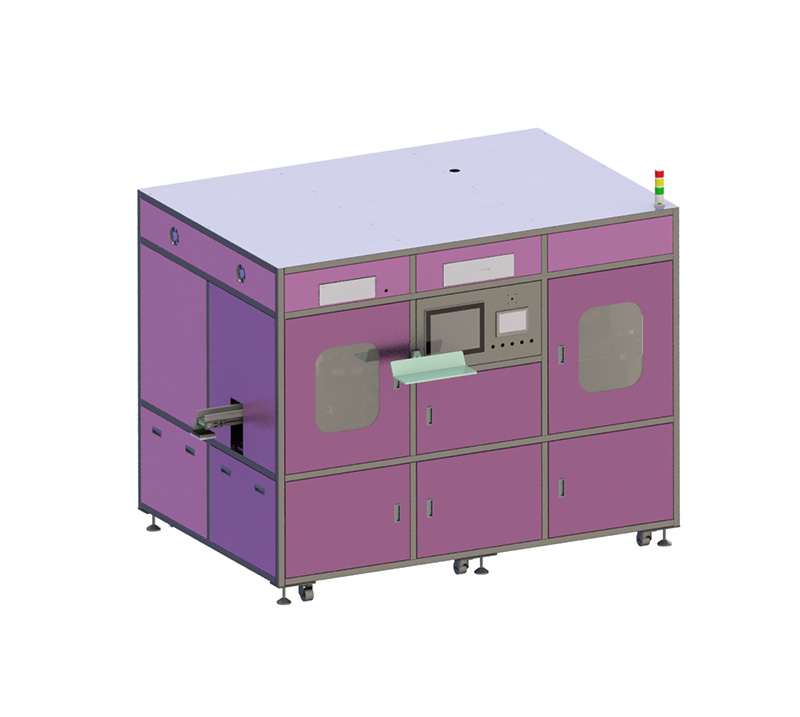

A specialized equipment for welding capacitor elements, which achieves automatic feeding, positioning, welding, flipping, welding, and jig reflow through jigs, cylinders, belts, etc. Suitable for automated assembly lines. The equipment needs to be manually installed with welding fixtures to the loading station, and the welding is completed with manual unloading.