This equipment is used for metallized film capacitor element clearing and sorting, the elements are supplied to the testing fixture of the host machine through the element feeding mechanism, and the elements clamped on the fixture move grid by grid and are electrically connected to the configuration of each test department to complete each inspection item. Through the inspection to determine whether the element is good or not, the defective products are classified and discharged, and the qualified products are sorted out by the transfer mechanism to the element unloading belt. The loading and unloading methods can be customized according to customer needs.

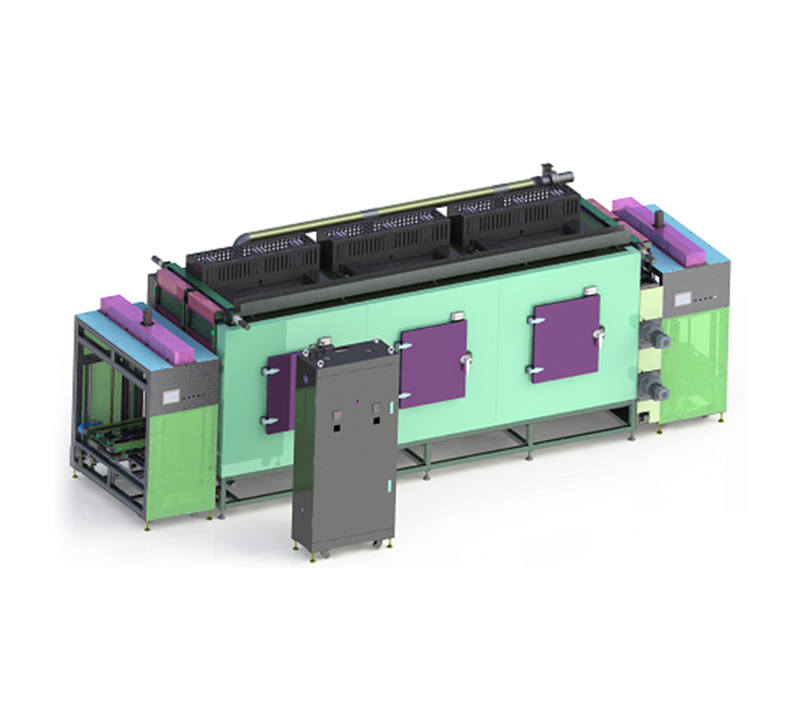

It is used for curing in-case capacitors before glue injection of four lead capacitors. The electric heating tube is the heat source, the blower realizes the internal circulation of the hot air, and realizes automatic feeding and discharging through jigs, cylinders, chains, etc. This equipment is a glue line equipment, and the heating time can also be customized according to customer needs.

This device is a 4 lead capacitor automatic shaping and gluing device.

Realize automatic vacuum suction of raw materials, automatic stirring, and heating vacuum to remove bubbles (umbrella shaped structure). The stirring tank is composed of a main agent tan and a hardening agent tank. The two raw materials are mixed using static mixing, and after mixing, it is automatically filled with glue in an atmospheric pressure environment. The glue filling method adopts a single jig with a single point of movement. This device is a glue filling line device.

It is used for curing in-case capacitors and glue after glue injection of four lead capacitors. The electric heating tube is the heat source, the blower realizes the internal circulation of the hot air, and realizes automatic feeding and discharging through jigs, cylinders, chains, etc. This equipment is a glue line equipment, and the heating time can also be customized according to customer needs.

This equipment is used to connect the capacitor products that come out of the curing furnace. The products and trays are cooled to room temperature through air cooling, and the products on the trays are unloaded and transported to a 4 lead capacitor testing machine.

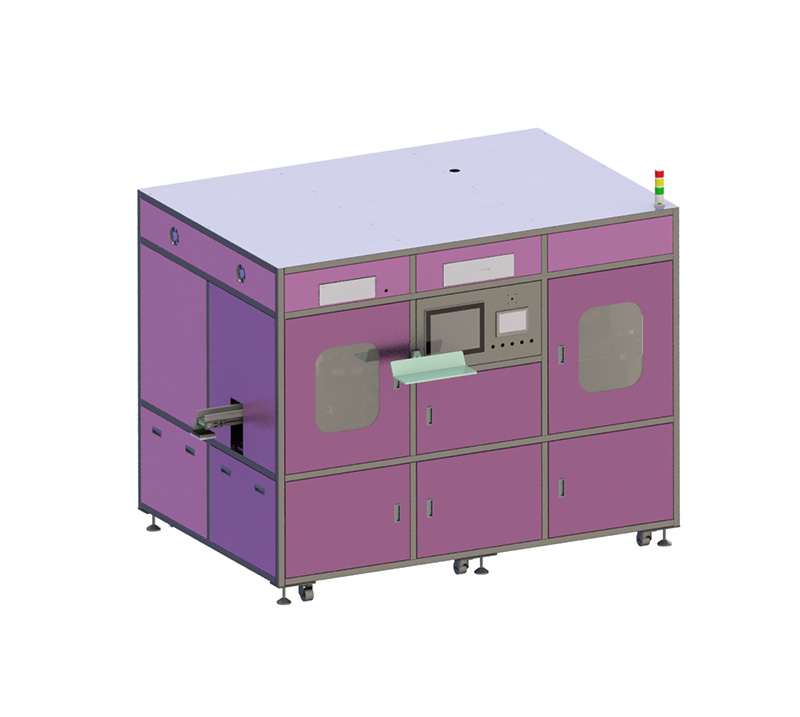

This equipment is a four lead capacitor automatic inspection and selection device.

It is composed of the product to be tested, the operating carrier, the circular slide rail, the detection mechanism, and the data processing device. The product is automatically fed into the operating carrier of the equipment through a conveyor belt, and then inspected one by one in each function. The detection data can be recorded and traced through an industrial computer, and defective and good products are discharged separately.