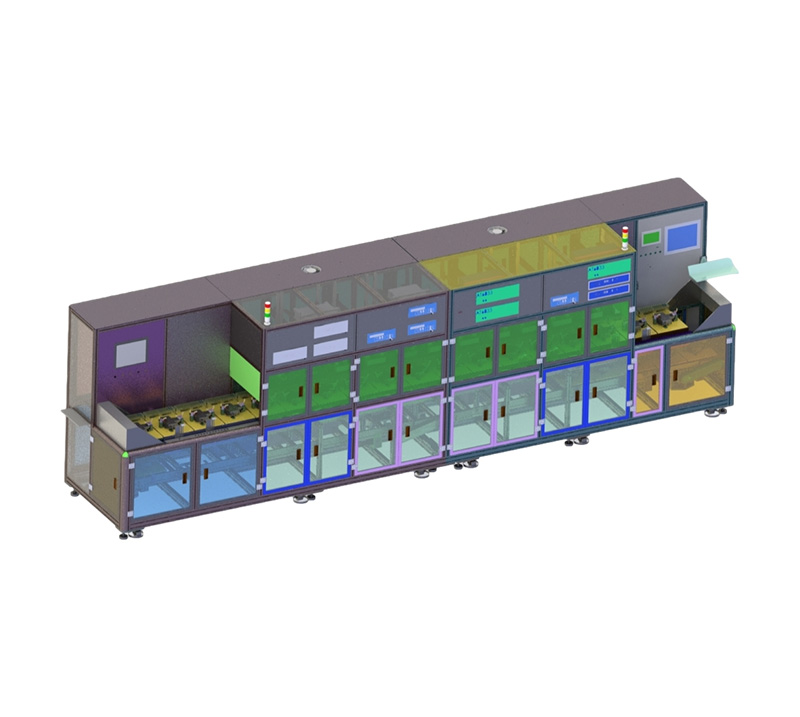

This equipment is a capacitor automatic inspection and selection device.

It consists of a structure for handling products to be tested, an inspection mechanism, and a data

processing device. The product is manually mounted on the fixture, moved along with the work

station, passed through the inspection mechanism of each work station, and inspected in sequence.

The product is judged to be good or bad according to the set contents of the inspection. The alarm is

generated when the defective product is moved to the defective product exit station, and after the

defective product is removed manually, the alarm is reset and the inspection continues to run.

Each inspection station can perform manual inspection independently.

The qualified products will be manually discharged at the qualified product discharging station.

Device Name | Testing Machine(linear type) |

Maximum product size | 350*300*150 |

Jig size | 303×167×96 |

Capacity measurement range (smooth) (Cs) | 0.01uF~1200μF |

Capacity measurement range (filtering) (Cf) | 0.01uF~1200μF |

Y Capacity measurement range (Cy1 Cy2) | 0.01uF~2μF |

Voltage range (DC) | Cs,Cf(2000VDC);Cy(5000VDC) |

Insulation resistance test (IR) | 100VDC 250VDC 500VDC 750VDC 1000VDC IR:1MΩ~1TΩ |

1KHz/10KHz capacitance loss test C-D | C:0.0001-250uF 1KHz D:0.0001-9.9999 1KHz/10KHz |

| Control system | PLC+Touch screen/PLC +Touch screen+Industrial computer/PC |

Efficiency | 1.5~2pcs/min |

Power supply | AC 380V, 3Φ,50/60Hz |

Power | Max.30KW |

Air pressure | 0.45-0.6Mpa |

Dimension(mm) | 6500 × 1250× 2200(L*W*H) |

Weight | 3500KG |

Color | RAL7035 |

Recommended Products