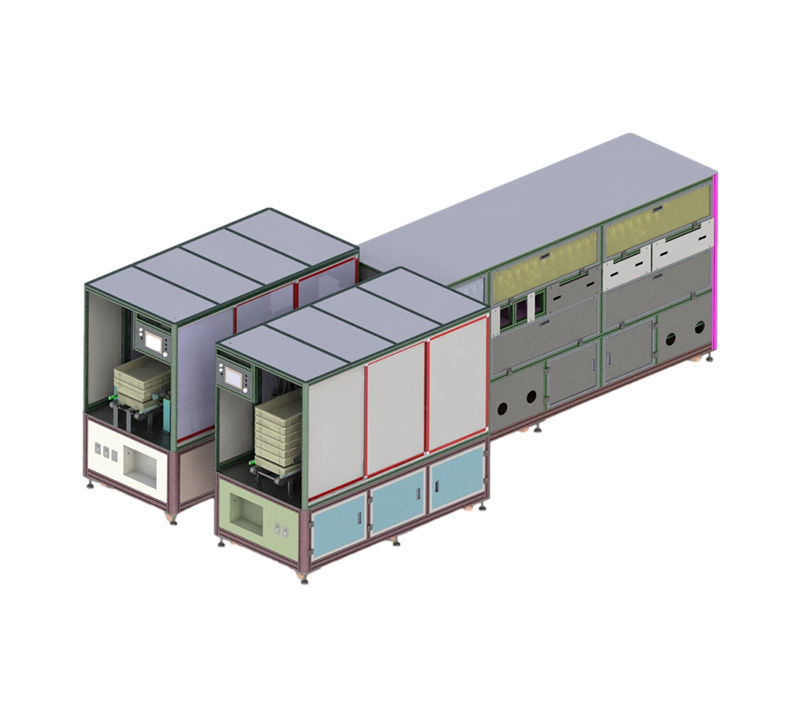

This equipment is used for metallized film capacitor element clearing and sorting, the elements are supplied to the testing fixture of the host machine through the element feeding mechanism, and the elements clamped on the fixture move grid by grid and are electrically connected to the configuration of each test department to complete each inspection item. Through the inspection to determine whether the element is good or not, the defective products are classified and discharged, and the qualified products are sorted out by the transfer mechanism to the element unloading belt. The equipment needs to be manually arranged to the special rubber frame for loading and unloading, and the loading and unloading method can be customized according to the customer's demand.

Device Name | Clearing Machine (linear type) |

Adapt to product size | W:25-65 B:26-80 T:15-45 |

Total number of stations | 54 |

Clearing voltage | AC:0-1000V,DC:0-5000V, DVDT:3000A |

1KHz/10KHz C-D test 10KHz ESR test (optional) | C:0.0001-250uF 1KHz D:0.0001-9.9999 1KHz/10KHz ESR:0.01mΩ-99.9999MΩ 10KHz(optional) |

Efficiency | 25-40pcs/min |

Control system | PLC+Touch screen/PLC +Touch screen+IPC/PC |

Power supply | AC 380V, 3Φ,50/60Hz |

Power | Max.35KW |

Air pressure | 0.45-0.6Mpa |

Dimension(mm) | 4950*2100*2000(L*W*H) |

Weight | 1800KG |

Color | RAL7035 |

Recommended Products